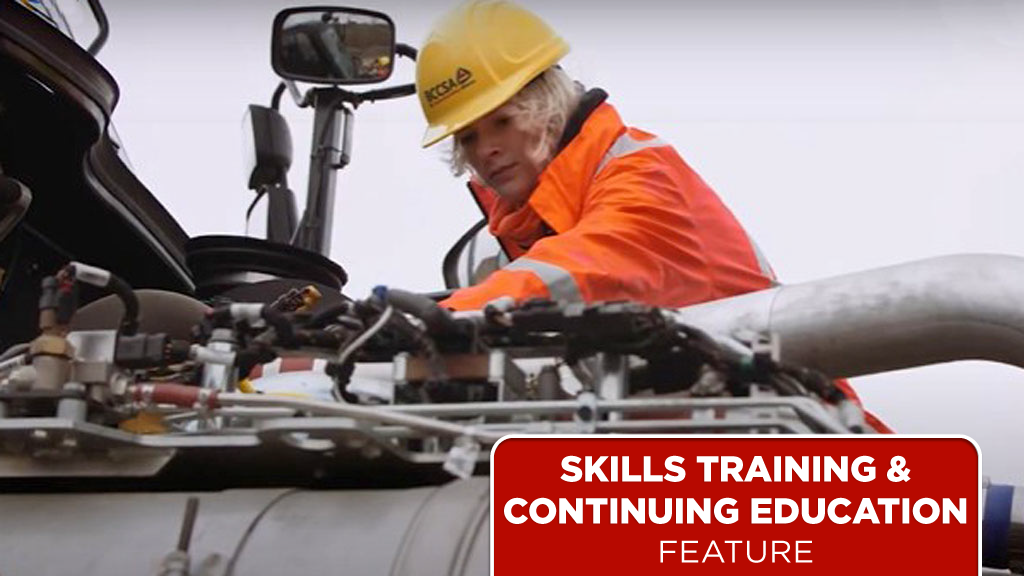

Emilie, an Abbotsford, B.C. youth, is sitting on a piece of heavy equipment, her blond hair tucked neatly under a yellow hardhat. She’s wearing an orange jacket with reflective stripes.

“Both of my brothers went through the trades and I wanted to follow that path as well,” she explains in a video. “I thought that I would enjoy being a heavy equipment operator the most.”

Jacob, another student, is standing at a site with a large yellow excavator in the background. He has a similar story.

“My dad and two uncles and grandfather were linemen and always working with heavy equipment, so I’ve been around it since I was little. At a very young age, I knew that I wanted to do the same.”

Emilie and Jacob share the passion of learning how to operate heavy equipment. They were participants in a heavy equipment operator training program offered by the Abbotsford School District in B.C.

While many people their age are learning to drive a car, they were behind the wheel of large pieces of heavy equipment, acquiring the skills to become an operator.

The course is the only one of its kind in B.C. and provides specialized hands-on career training to high school students in Grade 12. It runs from February to May and gives them a head-start on their quest to become a heavy equipment operator.

Students receive classroom instruction on the fundamentals of operating equipment, followed by time in the field. They earn graduation credits over an 11-week period which also apply to the first level of technical training associated with an Industry Training Authority (ITA) program or apprenticeship.

“It’s a fast-paced trades immersion program,” says Michael Pearson, district vice principal of career programs at the school district. “This year we’ve got some increased interest from our female audience so that’s good.”

Youth can apply to the program and selection is based on school marks, attendance record and other factors.

“We try to select the best people for the program, those that have the skills and the passion,” says Pearson.

There are 16 seats available in the annual course. The school district has never had a problem filling them.

As part of the course, students first participate in a classroom-based roadbuilder training program and, upon passing an exam, move to the second level which is a couple of weeks of hands-on instruction in the field, normally at an open mine site or gravel pit. They receive training on eight pieces of heavy equipment.

A typical day starts at 7:30 a.m. with an on-site safety meeting. The students do an inspection of the heavy equipment and, under the watchful eye of instructors, get to practice on the machines.

“This is an ITA-approved program,” notes Pearson. “It’s foundation training for both roadbuilders and heavy equipment operators.

“We start early and we run 12-hour days out there for these kids, or at least minimum 10. We’ve got to get them used to it.”

Upon completion of the course, students will have a foundation in roadbuilding and operating heavy equipment. They can then continue training and write an equipment-specific test for certification.

Pearson says the program is only possible because of support from civil contractors and rental equipment suppliers and partners like the B.C. Road Builders and Heavy Construction Association, Ministry of Transportation, Independent Contractors and Businesses Association, Hall Constructors, Riverside Equipment, TYBO, Jacobs Bros., Springline, CAT Rentals and Lafarge.

“It’s a program of partnerships because of the expense of the equipment. All the equipment is donated. We’ve got union and non-union representation.”

The school district has an educational agreement with Thompson Rivers University which provides ITA-qualified instructors for the program.

Acquiring the use of land for the program is always a challenge as seven to 10 acres are required. All the equipment and land are donated. The school district pays for fuel and transportation costs for the equipment and insurance and other costs for the program.

“We always have to have a couple of irons in the fire for the land,” says Pearson. “To be honest with you, sometimes we have all the equipment lined up but not the land. And some years, I’ve got the land but I don’t have the equipment. The show must go on. Somehow it all seems to come together.”

Sourcing heavy equipment can be difficult as contractors often need the machines.

“No one can commit six weeks in advance but the contractors that we’ve had on for several years believe in helping future operators,” says Pearson. “They see the value in having young operators freshly trained so that they can take on and continue that apprenticeship-mentorship.”

Students looking for a career in construction won’t have trouble finding a job, says Pearson, as every student who took the training last year got placed in the industry.

“When the donors address the class, they speak to them about their specific needs and what their company does, where they’re located, and highlight some of their jobs. Ultimately the kids will choose where they would like to go. They’re getting placed all over the Lower Mainland.”

Recent Comments

comments for this post are closed